Create Your First Project

Start adding your projects to your portfolio. Click on "Manage Projects" to get started

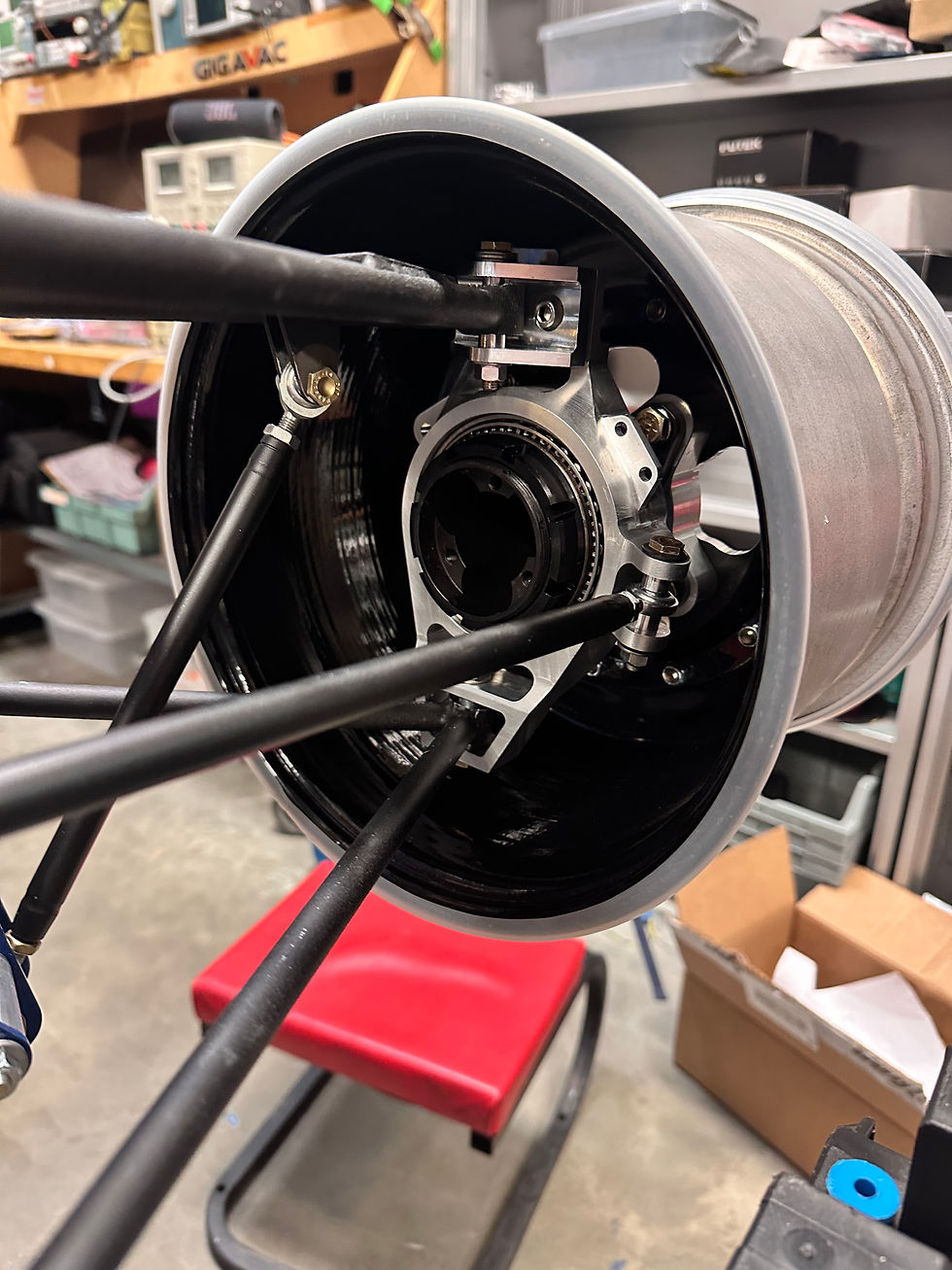

Formula SAE Knuckle

Olin Electric Motorsports is a student-run, Formula SAE Electric Team. We build a new car from the ground up, chassis, suspension, and all each design cycle. We are a small team with roughly 50 members, meaning members have a higher degree of freedom and ownership of their projects. I have been on the team throughout my time at Olin College of Engineering, starting off as a Suspension, Chassis, & Aero subteam member, then moving on to being the lead of the subteam in my sophomore year.

In my first year on the team, I designed the rear suspension geometry from a given list of characteristics. From this, I determined the car's rear caster, kingpin inclination, scrub radius, and general rear suspension geometry. As an extra challenge, I optimized the suspension geometry to create zero rear bump steer, a difficult but highly valuable outcome. This was all done in a 3D sketch with the entirety of the car's proposed geometry.

After a round of design reviews in front of teammates, senior engineers, and alumni, I began designing the rear knuckle/upright. This process required advanced CAD skills, with surfacing, dimensioning, and design for manufacturing. In roughly 6 weeks, I moved through multiple iterations, with 2 design reviews. During this process, I used FEA as well as Topology studies to influence my design choices. Within FEA, I created a suspension assembly to simulate all the forces under which a knuckle would go through. In the end, I was able to save roughly 30% weight compared to the previous year's knuckle.

Finally, I entered the fabrication process. Due to the Olin machine shops not having capable equipment, the main body of the knuckle was sent out to Kontrast4D, a machine shop in Salem, MA. This was an excellent opportunity for me to learn Geometric Dimensioning and Tolerancing (GD&T). I worked one-on=one with senior engineers to learn how to produce quality drawings. I also fabricated other components of the knuckle, such as the shim and clevis. These involved multiple operations on a mill, as well as fabricating some spacers using a lathe. The knuckle assembly ultimately was a complete success and helped the car be the best driving in Olin Electric Motorsports history.